Dust Collector Manufacturers

Ventilair India Private Limited is Best Industrial Dust Collector Machine Manufacturers in India We are Provide wide range of dust collector machine in Affordable Prices. Industrial Dust Collector Machines are helpful to maintaining a clean and safe working environment for workers.

In industrial and commercial settings, a dust collector is a device that is used to remove dust particles from the air to make breathing easier. A dust collector comprises a fan (or blower) that sucks in air from the environment which contains dust particles, a filter (or series of filters) that captures and divides the dust filled air into clean air and polluted air, and a bag or box that acts as a storage unit for the dust collected from the air. In woodworking and metalworking industries, a dust collector is used to improve air quality and protect the workers from harmful particles that can cause serious health issues. Dust collectors are also used in homes to get rid of indoor particles that can worsen allergy symptoms, thereby improving the general air quality of the house.

Types of Dust Collectors

Features of Dust Collectors:-

- Surface Grinding Machines Dust Collection system

- Wood Cutting Machinery Dust Collector

- CNC Cutting Machines Dust Collector

- Drilling Machines Dust Collection

- CNC Router Dust Collection

- Tool and Cutter Dust Collector Manufacturers

- Sand Blasting Machines Dust Collection

- Sharpening Machines Dust Collection

- Honing Machines Dust Collection

Industries We Serve:

- Woodworking Industries

- Food & Pharmaceutical Companies

- Bulk Powder Handling & Manufacturing Facilities

| Power (Hp / kW ) | 0.5 hp |

| No. of Bags | 2 |

| Power Source | Electrical |

| Voltage | 340 V |

| Brand | Ventilair India Private Limited |

| Dust Removal Efficiency (%) | 99% |

| Voltage (V) | 220 V |

| Frequency (Hz) | 50 Hz |

| Country of Origin | Made in India |

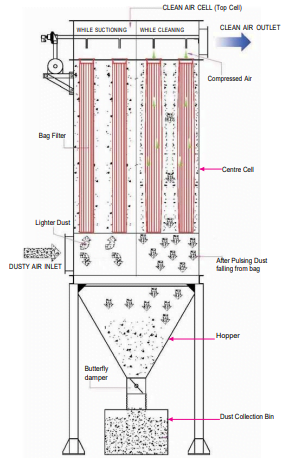

VENTILAIR Dust Collector extracts the dusty air/fumes from the dust/fume generating point through the duct connected to the Bag House of the Dust Collector. The dusty air is filtered in the Bag House. The Filtered air is exhausted at the top of the unit (Top Cell) and leaved in the atmosphere through the blower connected to chimney. The dusts are collected though the hopper in the dust bin. In this process filters do not get chocked, we use compressed air to clean the filters. The compress air is in the cylinder which is connected to solenoid valves. These Valves pass the compressed air thorough the G.I. pipe to filters when it got the single form electronic timer to pass the compressed air.

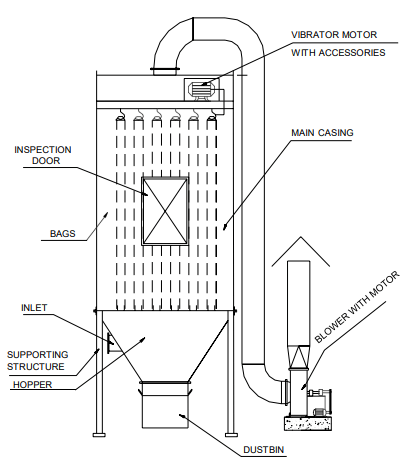

MECHANICAL SHAKING TYPE

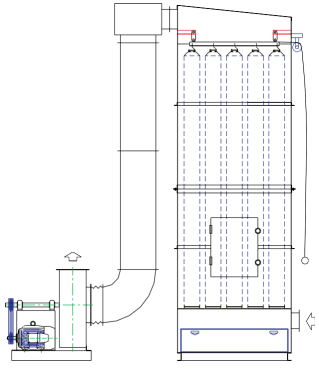

VENTILAIR Mechanical Dust Collector is characterized by a large pre-separator chamber in conjunction with an increased filter surface area and a vibrator motor for thorough cleaning of the high-capacity filter bag system. The result is an even finer dust filtration and greatly extended operating cycles between maintenance intervals.

The Mechanical Dust Collectors with high capacity filter bags and an optimized ratio of air flow versus filter surface area can be used as a central dust collection unit for multiple work stations or as a dust collector for large machines generating high volumes of dust.

The difference between Mechanical Dust Collectors is in the use of high-capacity bag filters, which have a considerably larger filter area than the Manual Dust Collector’s and can therefore collect much higher quantities of dust. The availability of this dust collector series in a wide range of configurations and with many options makes this model suitable for practically all types of industrial applications.

MANUAL SHAKING TYPE

VENTILAIR Manual Dust Collector Series was purposely designed as single station dust extraction units. All mechanical parts are integrated into a heavy duty sheet metal housing which rests on a base with built-in vibration dampers.

APPLICATIONS:-

Dust Extraction and collection equipment for dust generating machines in applications such as:

- Grinding, polishing, milling and sharpening.

- Filling processes of granular or powder substances.

- Production and bottling of pills and tablets.

- Send blasting applications in the metalworking industry.

- Surface finishing applications.

- Machine building industry.

- Chemical industry.

- Electro-mechanical industry.

How It Works:

- The dust collector bag is woven or non-woven material that filters out the dust particles.

- In most scenarios, the air is purified and cleansed because 99% of the dirt and dust particles are removed.

- The bag consists of a filter cloth dust collector bag that slips into the specially shaped designer bag. The hopper is located at the bottom end of the bag to collect the dust and dirt particles.

- When the industrial process starts, dirt and dust particles are released because of the operations. These particles are harmful to the environment and thus need to be collected. Therefore animal dust collectors are designed to capture these particles.

- During the process, dust particles are collected and begin to develop as thick layers inside the bag. This process is continuous. The thickened layer is removed in a careful manner with the aid of a mechanical shaker.

| Model | Power (hp) | Airflow (m ³/Hr) | Collection Capacity (litres) | Dimension LxBxH(m) |

|---|---|---|---|---|

| DCW1F1 | 1 | 1400 | 60 | 1.0×0.5×1.7 |

| DCW2F1 | 2 | 1850 | 80 | 1.0×0.5×1.8 |

| DCW2F2 | 2 | 1850 | 130 | 1.5×0.5×1.8 |

| DCW3F2 | 2 | 1950 | 170 | 1.5×0.5×1.8 |

| DCW5F2 | 5 | 2850 | 560 | 2.0×0.6×2.5 |

| DCW7F2 | 7.5 | 3500 | 750 | 2.0×0.6×2.6 |