WELCOME TO VENTILAIR INDIA PVT. LTD.

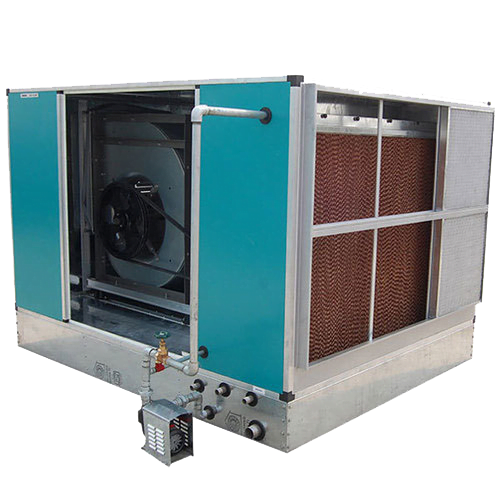

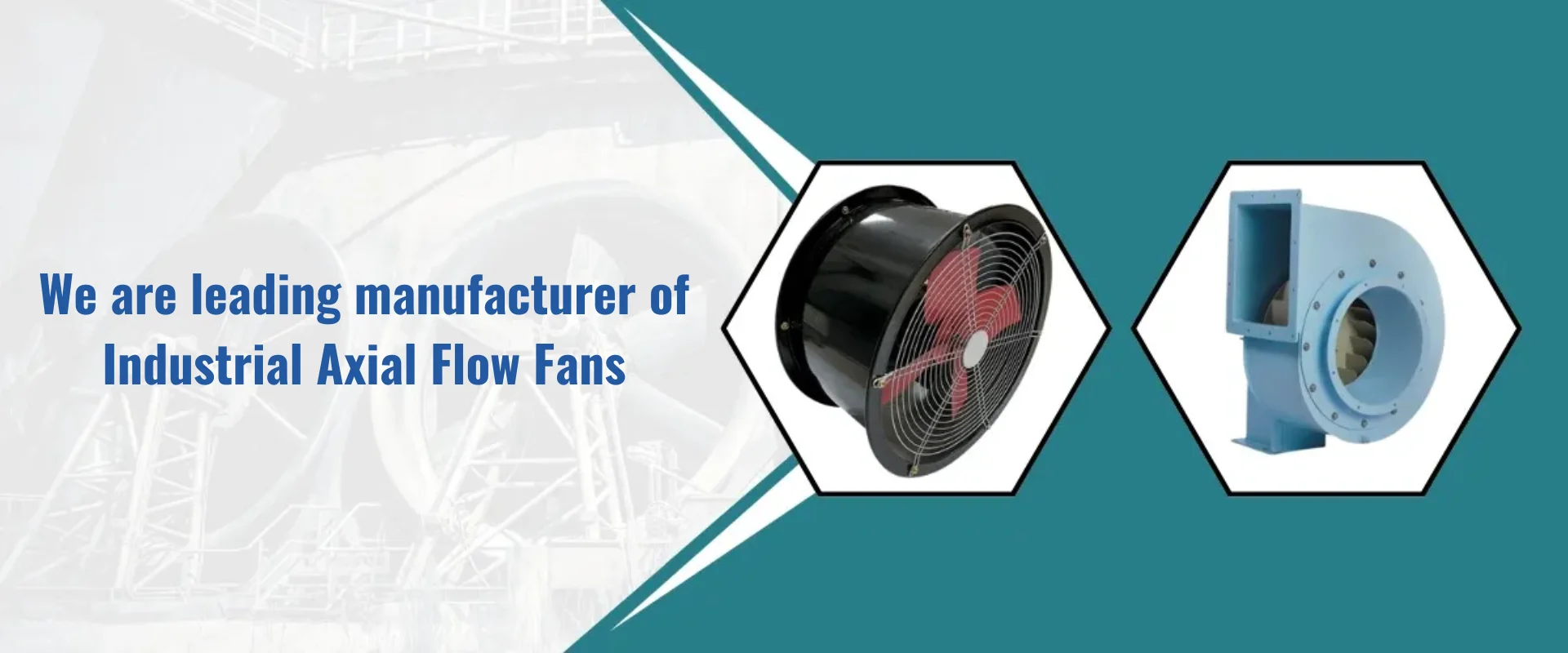

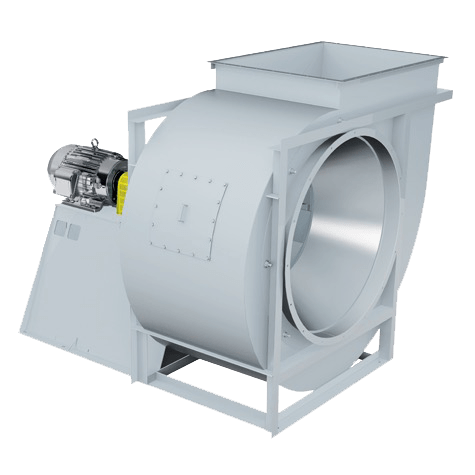

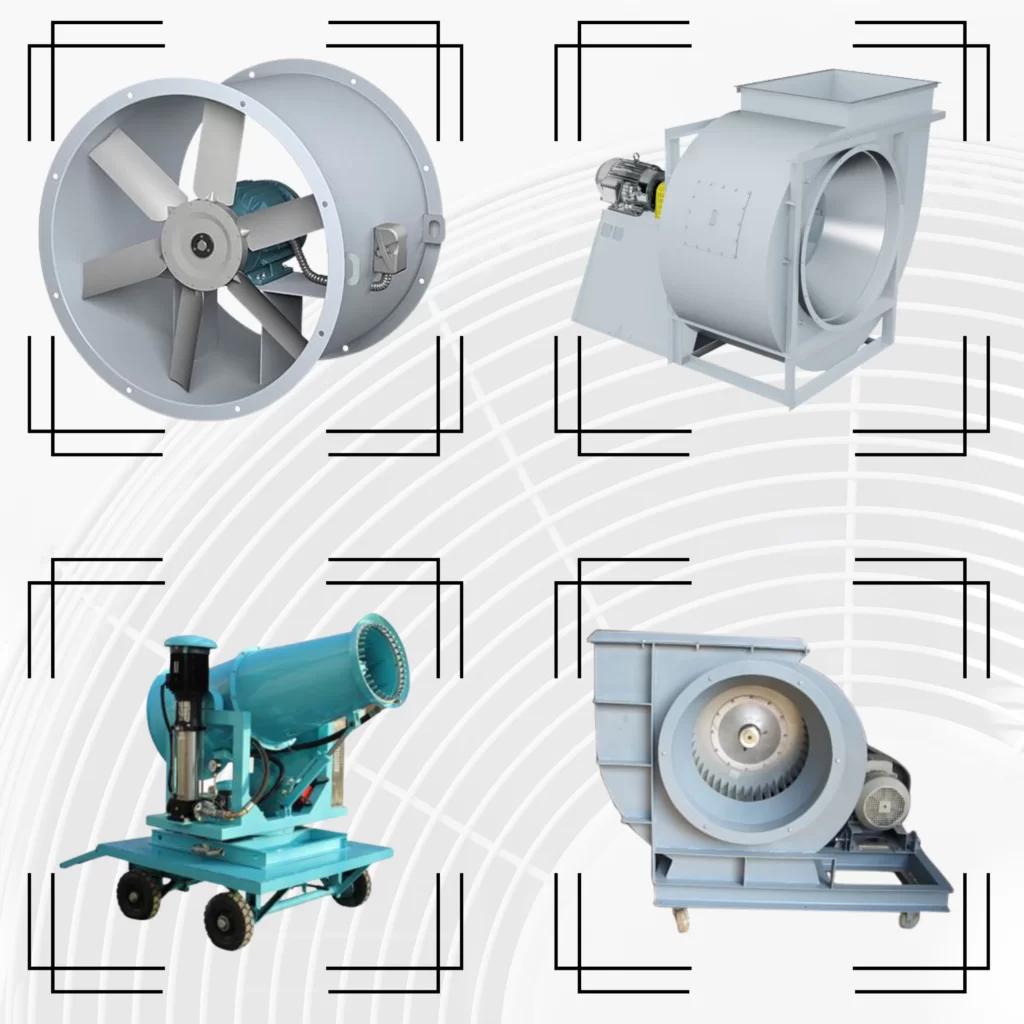

We Build the Best Quality of Centrifugal Blower, Axial Fans and Air Handling Equipments

Established in the year 1988 in Faridabad (Haryana, India), “Ventilair India Private Limited” is amongst the leading Manufacturers and Exporters of a wide variety of air pollution control systems and equipments. Our product range includes Air Cooling System, Industrial Scrubber, Pneumatic Conveying System, Ventilation System Equipment, Dust Collector, Metal Impeller, etc.

INDUSTRIES

We Serve

Hotels

Corporate Office

Malls

Hospitals

Manufacturing Industries

Retails

OUR PRODUCTS

We're Committed To Help Clients

- Our Mission

- Our Vision

- Quality Policy

Provider of Innovative engineering solutions in entire range of pressure & vacuum systems by having state of art technology, optimized designs, excellence in R&D, manufacturing and thrust on training & development of employees, continuously expanding our operations.

To become top solution provider by being a prominent and trusted brand for:

- Positive Displacement Blowers in the world

- Air Handling Unit in India

We at Ventilair are committed to continually improve in all process areas leading to quality product by involving competent and motivated employees at all levels leading to overall growth of the company through satisfied customers.

centrifugal blower and fans are best suitable for application

We Have Over 34 Years of Experience in This Industry

- Client's Satisfaction

Introducing New/ upgraded products better than the competitor, meeting customers’ expectations

- Value

Cost reduction by Value Engineering/ other methods, Wastage reduction

- Sustainable Goal

Achieving and sustaining superior levels of performance in all operations

- Services

Timely and effective customer support & services

Ventilair India Pvt. Ltd.

Our Clients

We have a large list of satisfied customers located in different parts of the world.